Royce Cambridge

Centred on the Maxwell Centre, the Royce facilities at the University of Cambridge are part of a UK-wide network of facilities funded by the Henry Royce Institute, the national institute for advanced materials research and development.

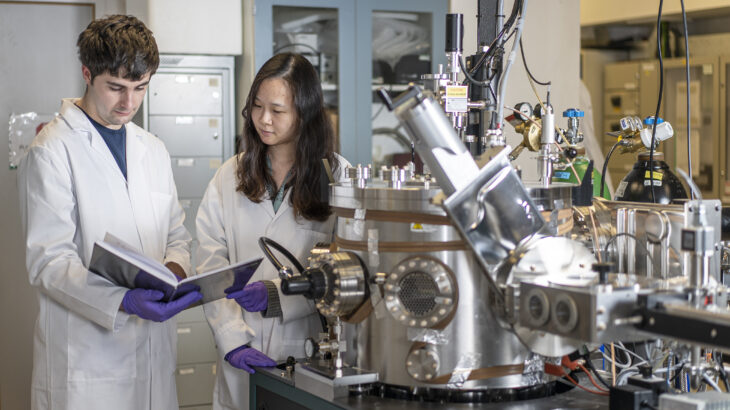

The state-of-the-art equipment available via Royce in West Cambridge enables the study of many different materials to support the development of energy efficient devices, plus the research of 2D Materials, Biomaterials and Bioelectronics development and Advanced Metals Processing. New materials systems can be fabricated and tested using a variety of equipment suites, including high resolution election-imaging and electrical testing. Most Royce facilities can be used independently by researchers and industry, with trained facility technical managers available to help shape projects and carry out bespoke analyses.

Background

The Royce facilities at Cambridge cover 18 different equipment suites that are used to support advanced materials research underpinning the energy transition. Based on feedback from industry and other research institutions, Royce at Cambridge has aimed to further develop the facilities available to best meet the needs of the wider materials community.

All Royce facilities are open to external users, with 28% of users from outside of the University of Cambridge. Researchers come from across the UK and internationally to use the Royce facilities at Cambridge, with 23 higher education institutions using the facilities over the past year.

Funding is available from the Royce Institute to support and encourage use by external researchers and SMEs. Between April 2023 and September 2024, there were 12,000 hours of use by external partners. Of that, 55% was by higher education and research organisations.

Researchers and students from non-Royce partner universities have benefited from Royce funding and access to facilities, in particular, members of the University of Strathclyde, Queens University Belfast, London South Bank University and Northumbria University have used the Royce facilities at Cambridge in the past two years.

Location

Cambridge is an ideal location for open-access facilities provided by Royce due to the proximity to the many spinouts in the East Anglia region. Cambridge’s links to London allows regular users easy access, including UCL, Imperial and Queen Mary University of London, with the nearby airports enabling a steady stream of researchers and industry to visit Cambridge from Europe and beyond.

Using the facilities

Royce facilities have a transparent charging model with users from Cambridge and other Higher Education Institutes charged the same rate for access, with a higher access rate for industrial users. Users have the opportunity in most cases to be trained to use the equipment independently, with staff on hand to provide analytical services to users. There is also the opportunity to involve skilled Royce Application Scientists on projects who are available to help users design research programmes and support work on short term projects.

User case studies

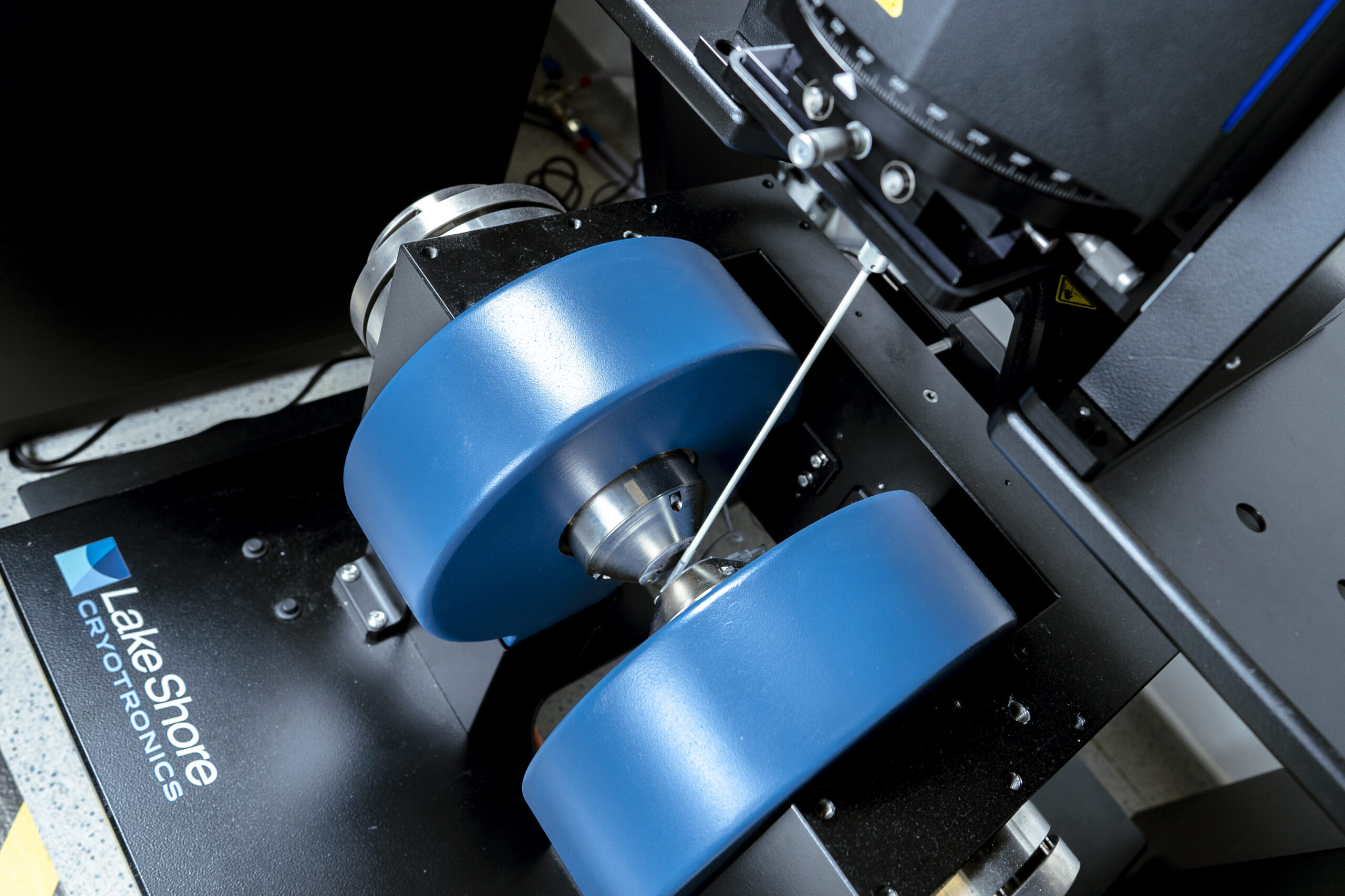

The Vibrating Sample Magnetometer (VSM) at the Royce Physical Vapour Deposition allowed researchers from the University of Portsmouth to analyse small, and thus challenging, samples of iron-core materials form magnets to study their magnetic behaviour. The Royce VSM at Cambridge had the exceptional capability to be able to study such small samples and to determine their magnetic saturation on the scales required.

Babak Haghighat Shishavan, the researcher on the project from the University of Portsmouth, said that he had learned a great deal from colleagues at Cambridge on how to operate the VSM and how to analyse the collected data. “Considering the special conditions of my samples and my research and with the small sample sizes I had available, I would not have been able to easily perform these experiments without Royce at Cambridge”.

Some 35% of the Royce Cambridge’s users are from SMEs. One SME customer is Polysolar and access to the Ambient Processing Cluster Facility has enabled the company to develop products and attract further funding for research into new transparent solar devices. The Ambient Processing Cluster Facility provides the ideal range of equipment and the environment required for photovoltaic device fabrication, deposition, packaging, and testing, fulfilling a national need within this type of technology.

Martyn Rush, R&D Manager at Polysolar, said: “The cluster tool at the Maxwell Centre in Cambridge has allowed Polysolar to realise its research ambitions of transparency in Organic Photovoltaic material using the latest materials and techniques, on top of this the collaboration has raised the profile of the project to enable further funding from Supergen Supersolar.”

Funding

The Royce facilities at Cambridge were funded through an initial capital investment of £12m from the Engineering & Physical Sciences Research Council. The University of Cambridge provided the space for the facilities and equipment, including in the Maxwell Centre – the University’s hub for industry-academia interactions. The Henry Royce Institute has provided additional funding to support external access, with most equipment access funded by UKRI research grants and external industry access fees.

Facility contact

Dr Andrew J Dobrzanski

Royce Research and Business Engagement Manager